Changing Maintenance with the Transformer Oil Regeneration Process

Changing Maintenance with the Transformer Oil Regeneration Process

Blog Article

Cost-Effective and Eco-Friendly Transformer Maintenance With Regenerated Oil

The integration of regenerated oil in transformer upkeep offers an engaging strategy for companies looking for to improve both cost-efficiency and eco-friendliness. By making use of oil that keeps efficiency requirements akin to virgin alternatives, organizations can dramatically minimize operational costs while simultaneously lessening their ecological impact.

Understanding Regenerated Oil

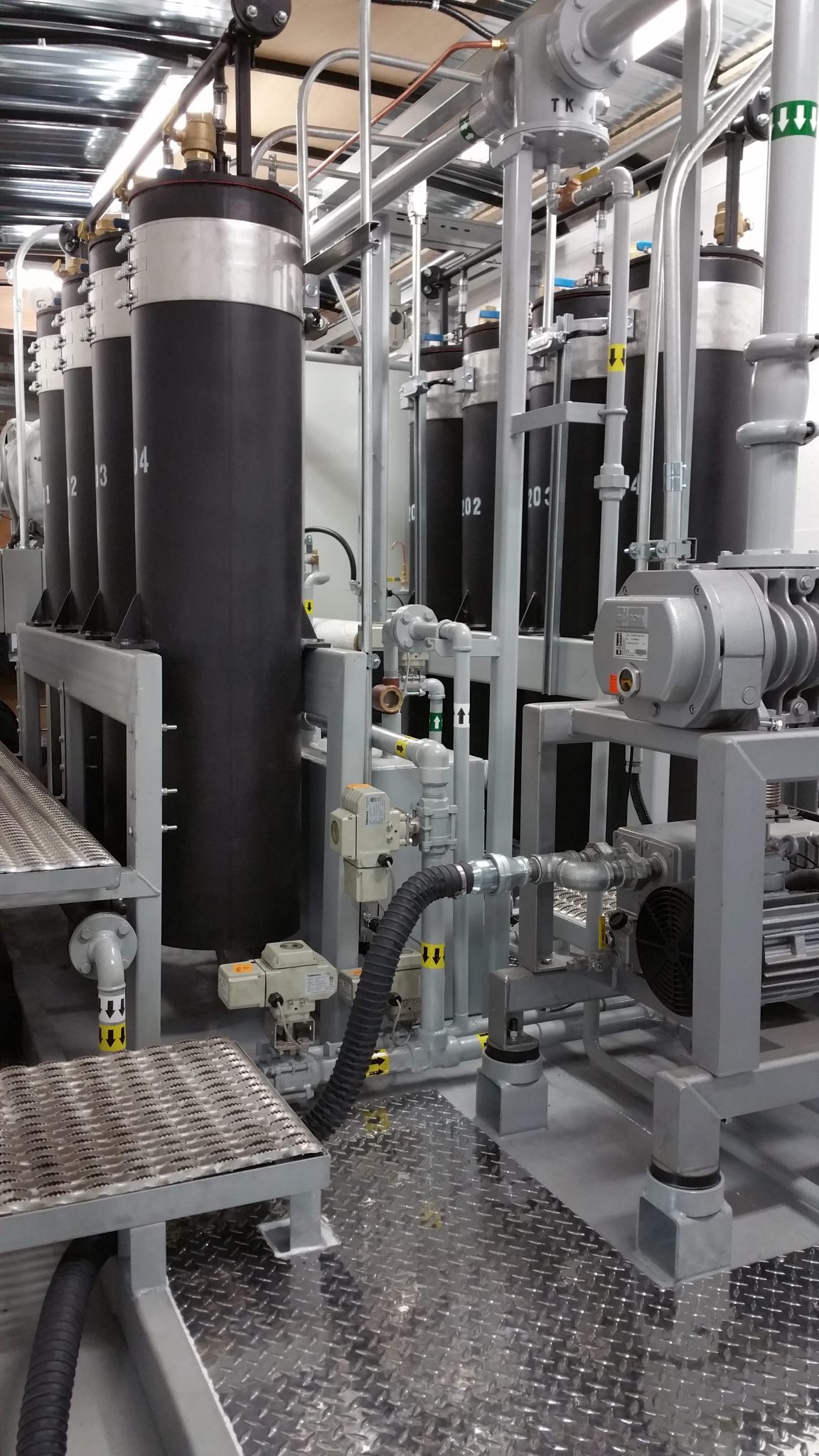

Regenerated oil, frequently referred to as re-refined oil, is a crucial part in the upkeep of transformers, giving both environmental and financial benefits. This oil is stemmed from used mineral oils that have actually undergone a detailed purification procedure, efficiently removing impurities and restoring the oil to a high quality similar to virgin oil. The regrowth process typically involves numerous stages, consisting of physical splitting up, chemical therapy, and purification, ensuring that impurities such as sludge, water, and hefty steels are gotten rid of.

The application of restored oil in transformers is important for optimizing efficiency and expanding equipment lifespan. High-grade re-refined oil maintains its dielectric buildings, guaranteeing efficient insulation and preventing electric break downs. In addition, it possesses exceptional thermal conductivity, which helps in managing the operational temperature levels of transformers, inevitably enhancing their reliability and performance.

Moreover, embracing regrowed oil not only supports cost-effective upkeep approaches however likewise lowers the demand for new oil production, thereby conserving natural deposits. Transitioning to re-refined oil is a smart selection for organizations aiming to maintain high operational requirements while all at once handling spending plan constraints. Recognizing the residential or commercial properties and benefits of restored oil is crucial for informed decision-making in transformer maintenance techniques.

Environmental Benefits

Using regrowed oil in transformer maintenance uses considerable ecological advantages that add to lasting practices within the energy sector. Among the key benefits is the decrease of waste oil disposal, as regenerated oil is obtained from the recycling of made use of transformer oil, considerably lowering the quantity of contaminated materials created. This procedure assists reduce the environmental risks connected with improper disposal approaches, which can bring about soil and water contamination.

Furthermore, the regrowth process saves natural deposits by minimizing the requirement for brand-new base oil production - Reclaimed Transformer Oil. This conservation effort not just lowers the removal effect on ecosystems however additionally lowers the carbon footprint connected with oil production. By embracing regenerated oil, business can further their commitment to ecological stewardship and straighten with international sustainability objectives

Moreover, using restored oil improves the overall performance of transformers, leading to minimized power losses and lower greenhouse gas discharges. As the energy field significantly encounters pressure to diminish its ecological effect, welcoming regrowed oil represents a proactive approach to attaining both operational and eco-friendly goals. In recap, the environmental advantages of making use of regenerated oil are diverse, promoting a healthier earth while supporting the power market's transition in the direction of sustainability.

Cost Cost Savings and Efficiency

Utilizing regenerated oil in transformer upkeep can lead to significant price financial savings and improved functional effectiveness for power companies. Regrowed oil, generated via advanced filtration procedures, offers comparable performance to brand-new oil at a fraction of the expense. By recycling oil that would certainly or else be disposed of, companies can minimize their buying costs while lessening garbage disposal expenses.

Furthermore, the extended life process of restored oil translates to lowered regularity of oil adjustments, resulting in reduced labor costs and minimized downtime for maintenance tasks. Transformer Oil Regeneration Plant. This not only improves operational performance however likewise enables an extra streamlined upkeep timetable, allowing companies to allocate sources better

On top of that, making use of regenerated oil can bring about lower insurance coverage costs as a result of its eco-friendly profile. As energy companies deal with raising examination concerning their environmental effect, taking on lasting techniques such as utilizing regrowed oil can strengthen their track record and possibly draw in financial investment.

Inevitably, the integration of regrowed oil right into transformer upkeep techniques offers a strategic opportunity for energy companies to achieve considerable price financial savings while advertising functional performance, therefore aligning financial performance with environmental responsibility.

Comparison With Traditional Oils

While traditional oils have long been the requirement in transformer maintenance, a complete comparison exposes that regenerated oils provide several benefits that boost performance and sustainability. Conventional mineral oils, while effective, often posture environmental dangers, such as contamination and disposal concerns. On the other hand, regenerated oils are stemmed from recycled products, dramatically lowering their environmental footprint.

One of the vital differentiators is the chemical stability of regenerated oils. They generally exhibit exceptional oxidative stability, which translates to longer solution life and minimized frequency of oil modifications. This particular not only improves transformer efficiency but additionally decreases downtime and maintenance expenses. In addition, regenerated oils typically have lower levels of unsafe ingredients, making them a safer option for both tools and the environment.

This high quality is essential in maintaining transformer capability under differing operational conditions. On the whole, the advantages of regenerated oils over traditional oils highlight their prospective to change transformer upkeep techniques, providing a much more responsible and reliable choice.

Application in Upkeep Practices

As soon as the evaluation is total, a customized strategy for transitioning to regrowed oil needs to be created, thinking about aspects such as compatibility with existing materials and operational problems. Educating for maintenance personnel is important, as they should understand the unique homes of regenerated oils and just how to manage their application efficiently.

Implementing a rigorous surveillance program will facilitate the evaluation of efficiency metrics post-implementation, guaranteeing the regrowed oil meets the called for operational requirements. Transformer Oil Regeneration. Furthermore, developing a regular maintenance timetable will help in determining possible concerns early and permit timely rehabilitative activities

Verdict

To conclude, the adoption of regenerated oil for transformer maintenance provides a sensible remedy that straightens financial advantages with ecological sustainability. By minimizing prices related to oil adjustments and garbage disposal, while simultaneously extending the life-span of tools, companies can improve functional effectiveness. The transition to regenerated oil not just alleviates environmental discover here impacts but additionally sustains wider sustainability objectives, making it a sensible option for modern-day upkeep techniques in the power market.

Regenerated oil, usually referred to as re-refined oil, is an essential element in the maintenance of transformers, giving both economic and ecological benefits. This oil is obtained from made use of mineral oils that have undergone a thorough purification procedure, effectively eliminating impurities and restoring the oil to a quality similar to virgin oil.Additionally, adopting regrowed oil not only sustains cost-effective upkeep techniques yet image source additionally lowers the demand for brand-new oil manufacturing, thus preserving all-natural sources. One of the main advantages is the decrease of waste oil disposal, as regenerated oil is acquired from the recycling of utilized transformer oil, dramatically lowering the quantity of unsafe waste created. Regrowed oil, created via advanced purification procedures, offers equivalent efficiency to new oil at a fraction of the cost.

Report this page